Many cosmetic manufacturers produce their own multi-ingredient base raw materials (mixtures) that are then used in their finished product formulas. Examples include:

- base soaps

- essential oil blends

- gels

- herbal infusions (see below, ‘The ‘herbal infusion’ problem’)

To manage these correctly in Product Manager, you must follow these two steps:

- create the multi-ingredient base raw material as a product;

- set up corresponding raw material batches for the product.

The advantages of this approach are as follows:

- you can add other multi-ingredient raw materials to your product composition;

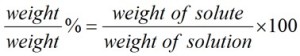

- the %w/w ingredient breakdown will be correctly calculated;

- inventory will be correctly managed for all raw materials;

- batch traceability for your own multi-ingredient base raw material is possible;

- you can also manage your multi-ingredient raw material as a product – useful if you plan to also sell this and require compliance with any regulations and GMP, such as generating a PIF or batch protocols.

Example – Aloe vera gel

Your company purchases the preservative Euxyl PE 9010 which is a 90/10 mixture of Phenoxyethanol and Ethylhexylglycerin. This has firstly been created as a multi-ingredient raw material in Product Manager under the trade name “Euxyl PE 9010” with the correct composition. Let’s assume that you want to create an Aloe gel that contains 1% Euxyl PE 9010 and uses this Aloe gel as either a finished product or as a base in other formulations. Because of this, Aloe gel needs to be setup both as a product and as a raw material. To correctly manage this scenario, you need to do the following:

- Create a product named e.g. ‘Aloe Gel’ and add the Euxyl PE 9010 raw material @1% w/w concentration in the formula’s ‘Composition’ tab, along with the Aloe vera and any other required ingredients.

- Under Formula/Specification, click on the ‘2. Compliance’ tab to obtain the %w/w ingredients breakdown for the formula.

- Use the manufacturing order feature to manufacture the ‘Aloe Gel’ product.

- Create a raw material called ‘Aloe Gel’. In the ‘Composition’ tab, enter the ingredients and their percentages, as shown in step 2.

- For each batch of your Aloe Gel product that is manufactured, set up a corresponding batch of the Aloe Gel raw material, including the inventory and entering your own company as the supplier/manufacturer, as well as assigning a raw material batch number.

You can now use these batches of your Aloe Gel raw material in any of your products. The correct %w/w for each ingredient will be calculated in the product’s formula and manufacturing any product using the Product Manager’s manufacturing orders will ensure that inventory is correctly deducted from your available Aloe Gel raw material batches.

The ‘Herbal infusion’ problem

One complication to the above described method can occur when your base raw material contains one or more ingredients added at the beginning of the production process that are later removed. This is common for example, in herbal infusions whereby the flower petals are removed from the oil at the end of the manufacturing process.

For regulatory purposes, it is always the final composition of the raw material that must be entered and not the ingredients used at the start of the manufacturing process. To determine this final composition, you will need to either:

- follow an exact formula and method that has a known final ingredient composition in %w/w;

- enter maximum %w/w values with safe margins for any restricted ingredients, to ensure any thresholds will not be reached;

or:

- have your final infusion tested for the actual ingredient breakdown.

Using either of the above approaches, you then set up the herbal infusion as a raw material. In the raw material’s ‘Composition’ tab, enter the Min. %w/w and Max. %w/w (or Exact) ranges determined by one of the methods above, to ensure that the final ingredient breakdown falls within a specified concentration range. Because it is possible to also enter these ingredients in ranges, it should be possible to determine a min. and max. %w/w of the ingredients in the final infusion.

If none of the herbal ingredients in the infusion are restricted, the final ingredient breakdown of your formula (in the ‘Compliance’ tab of the formula level), will not cause compliance issues. However, if any ingredient is regulated, please contact your safety assessor to establish an acceptable method for determining the final max. %w/w concentration of the ingredient in your product.

If any of these ingredients are regulated, you must assume the max. %w/w value as the value to use for assessing whether any product formula using the infusion falls within acceptable concentration levels.